Business Owner's "Made In America" Experiment: Lessons Learned

Welcome to your ultimate source for breaking news, trending updates, and in-depth stories from around the world. Whether it's politics, technology, entertainment, sports, or lifestyle, we bring you real-time updates that keep you informed and ahead of the curve.

Our team works tirelessly to ensure you never miss a moment. From the latest developments in global events to the most talked-about topics on social media, our news platform is designed to deliver accurate and timely information, all in one place.

Stay in the know and join thousands of readers who trust us for reliable, up-to-date content. Explore our expertly curated articles and dive deeper into the stories that matter to you. Visit Best Website now and be part of the conversation. Don't miss out on the headlines that shape our world!

Table of Contents

Business Owner's "Made in America" Experiment: Lessons Learned – A Case Study in Reshoring

The allure of "Made in America" is undeniable. For many consumers, it signifies quality, supports domestic jobs, and boasts a patriotic appeal. But for businesses, the reality of reshoring – bringing manufacturing back to the US – is far more complex than a simple tagline. One entrepreneur, Sarah Miller, owner of the thriving small business "Miller's Crafts," recently completed a bold experiment: transitioning her entire production line from overseas to American-made materials and labor. Her journey offers invaluable lessons for other businesses considering a similar shift.

The Allure and the Challenges of Reshoring

Miller's Crafts, known for its handcrafted wooden toys, previously relied on overseas manufacturers for cost-effectiveness. However, rising shipping costs, extended lead times, and concerns about quality control prompted Miller to explore reshoring. While the "Made in America" label promised a boost in brand image and customer loyalty, the transition wasn't without its hurdles.

Key Takeaways from Miller's Experiment:

-

Higher Initial Costs: The most significant challenge was the increased cost of materials and labor in the US. Miller found that domestic sourcing was initially significantly more expensive than her previous overseas operations. This required a strategic price adjustment and a focus on highlighting the superior quality and ethical sourcing to justify the higher price point.

-

Finding Skilled Labor: Securing skilled craftspeople proved difficult. Miller invested heavily in training programs and apprenticeships to develop the workforce needed to maintain her production standards. This long-term investment, while initially costly, ultimately paid off in improved product quality and employee loyalty.

-

Supply Chain Complexity: Navigating the complexities of the American supply chain presented unexpected challenges. Sourcing high-quality, domestically produced wood required extensive research and relationship-building with local suppliers. This highlighted the importance of developing strong, reliable supplier networks.

-

Marketing the "Made in America" Advantage: Miller leveraged the "Made in America" aspect of her products heavily in her marketing strategy. This resonated strongly with her target audience, leading to increased sales and brand loyalty. She successfully communicated the value proposition of higher quality, ethical production, and support for American jobs.

-

Government Support and Resources: Miller benefited from several government programs designed to support domestic manufacturing. She utilized resources such as the Small Business Administration (SBA) and explored local and state incentives aimed at attracting and supporting small businesses. Researching and leveraging these resources is crucial for businesses considering reshoring.

H2: Long-Term Benefits Outweigh Initial Hurdles

Despite the initial challenges, Miller's experiment proved successful. While profitability took a slight dip initially, the long-term benefits – enhanced brand reputation, improved product quality, and stronger customer relationships – significantly outweighed the initial costs. The "Made in America" label became a powerful marketing tool, differentiating her products from competitors and commanding a premium price.

H3: Is Reshoring Right for Your Business?

Miller's story underscores the complexities of reshoring. It's not a decision to be taken lightly. Businesses considering this transition should conduct thorough due diligence, carefully weigh the costs and benefits, and develop a robust strategic plan. This includes:

- A comprehensive cost-benefit analysis: Compare the costs of domestic and overseas production, considering all factors, including labor, materials, shipping, and taxes.

- Market research: Analyze the demand for "Made in America" products within your target market.

- Supplier network development: Identify and build relationships with reliable domestic suppliers.

- Workforce planning: Determine the skills needed and develop a plan to acquire or train the necessary workforce.

The "Made in America" movement offers significant potential, but businesses need a realistic understanding of the challenges involved. Sarah Miller’s journey serves as a powerful case study, demonstrating that with careful planning, strategic investment, and a commitment to quality, reshoring can lead to significant long-term success. Learn more about resources available to businesses exploring reshoring by visiting the [link to SBA website].

Call to Action (subtle): Are you considering reshoring your production? Share your thoughts and experiences in the comments below.

Thank you for visiting our website, your trusted source for the latest updates and in-depth coverage on Business Owner's "Made In America" Experiment: Lessons Learned. We're committed to keeping you informed with timely and accurate information to meet your curiosity and needs.

If you have any questions, suggestions, or feedback, we'd love to hear from you. Your insights are valuable to us and help us improve to serve you better. Feel free to reach out through our contact page.

Don't forget to bookmark our website and check back regularly for the latest headlines and trending topics. See you next time, and thank you for being part of our growing community!

Featured Posts

-

Russia Ukraine Talks A Day Of Confusion And Breakthrough After Three Year Hiatus

May 17, 2025

Russia Ukraine Talks A Day Of Confusion And Breakthrough After Three Year Hiatus

May 17, 2025 -

Rediscovering Cannes Hilarious And Unexpected Images Before Camera Phones

May 17, 2025

Rediscovering Cannes Hilarious And Unexpected Images Before Camera Phones

May 17, 2025 -

High Court Rejects Roberts Smiths Appeal War Crimes Accusations Stand

May 17, 2025

High Court Rejects Roberts Smiths Appeal War Crimes Accusations Stand

May 17, 2025 -

Tragedy On The Mountain 3 Climbers Killed 1 Survives 400 Foot Fall

May 17, 2025

Tragedy On The Mountain 3 Climbers Killed 1 Survives 400 Foot Fall

May 17, 2025 -

Analyzing The Shift In American Spending Post Trump Tariffs

May 17, 2025

Analyzing The Shift In American Spending Post Trump Tariffs

May 17, 2025

Latest Posts

-

Major Revisions To Assisted Dying Bill Implications For England And Wales

May 17, 2025

Major Revisions To Assisted Dying Bill Implications For England And Wales

May 17, 2025 -

Los Angeles Angels Season Crumbles Injuries And Jansens Poor Performance Fuel Basement Ranking

May 17, 2025

Los Angeles Angels Season Crumbles Injuries And Jansens Poor Performance Fuel Basement Ranking

May 17, 2025 -

Ukraine Peace Talks Us Suggests Trump Putin Key To Breakthrough

May 17, 2025

Ukraine Peace Talks Us Suggests Trump Putin Key To Breakthrough

May 17, 2025 -

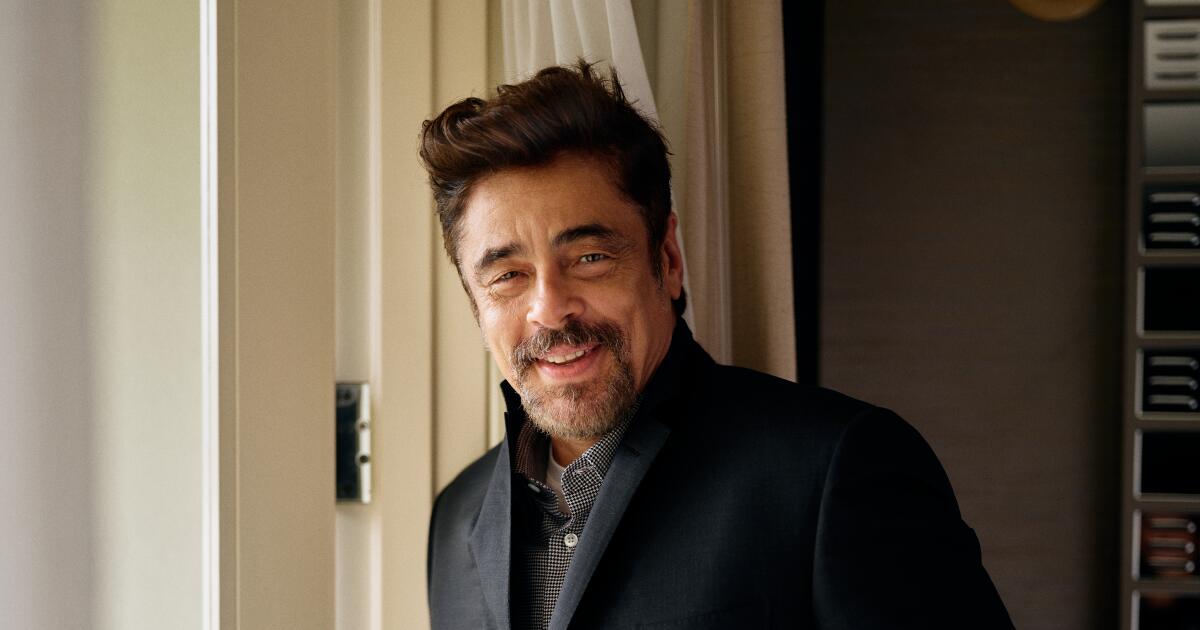

Benicio Del Toro And The Scheme Details Of A Surprising Present

May 17, 2025

Benicio Del Toro And The Scheme Details Of A Surprising Present

May 17, 2025 -

Dodger Roster Move Triple A Pitcher Joins Major League Team

May 17, 2025

Dodger Roster Move Triple A Pitcher Joins Major League Team

May 17, 2025