"Made In America" Test Yields Unexpected Results For Business Owner

Welcome to your ultimate source for breaking news, trending updates, and in-depth stories from around the world. Whether it's politics, technology, entertainment, sports, or lifestyle, we bring you real-time updates that keep you informed and ahead of the curve.

Our team works tirelessly to ensure you never miss a moment. From the latest developments in global events to the most talked-about topics on social media, our news platform is designed to deliver accurate and timely information, all in one place.

Stay in the know and join thousands of readers who trust us for reliable, up-to-date content. Explore our expertly curated articles and dive deeper into the stories that matter to you. Visit Best Website now and be part of the conversation. Don't miss out on the headlines that shape our world!

Table of Contents

"Made in America" Test Yields Unexpected Results for Business Owner: A Case Study in Reshoring

The allure of "Made in America" is undeniable. For many business owners, bringing production back to the US promises quality control, job creation, and a boost to national pride. But the reality, as one entrepreneur recently discovered, can be far more complex than the marketing slogans suggest. This case study explores the unexpected outcomes of a bold decision to reshore manufacturing, offering valuable lessons for businesses considering a similar move.

From Overseas to Ohio: The Journey Begins

Sarah Miller, owner of Miller's Fine Furniture, had been outsourcing production to Vietnam for over a decade. Driven by rising labor costs overseas and a growing desire to support American workers, she decided to bring furniture manufacturing back to her home state of Ohio. She invested heavily in new machinery, hired local craftspeople, and sourced American-made materials – a significant commitment to the "Made in America" movement. Initial projections predicted a slight increase in production costs, offset by the positive brand image and potential for increased sales.

Unexpected Challenges: More Than Meets the Eye

The reality, however, proved far more nuanced. While Miller was able to maintain the quality she desired, several unforeseen challenges emerged:

-

Higher-Than-Expected Labor Costs: While Miller was committed to fair wages, labor costs in Ohio proved significantly higher than initially projected, impacting profitability. This highlights the importance of thorough market research and realistic budgeting when planning a reshoring initiative.

-

Supply Chain Bottlenecks: Securing consistent supplies of high-quality American-made materials proved more challenging than anticipated. Lead times were longer, and finding reliable suppliers with the necessary capacity required extensive networking and relationship building. This underscores the need for proactive supply chain management strategies.

-

Increased Transportation Costs: Shipping finished goods across the country incurred higher costs compared to importing from overseas, further impacting the bottom line. Miller's experience highlights the need for a comprehensive analysis of transportation logistics and potential cost-saving measures.

-

Unexpected Marketing Hurdles: While the "Made in America" label held strong appeal, Miller found that communicating the value proposition to consumers required a more sophisticated marketing strategy than she had initially anticipated. Simply stating "Made in America" wasn't enough; she needed to highlight the superior craftsmanship and sustainability of her products.

Lessons Learned: A Path Forward for Reshoring

Miller's experience, while initially challenging, offers valuable insights for other businesses considering reshoring:

- Thorough Due Diligence: Conduct extensive market research, including a comprehensive cost-benefit analysis, to accurately assess the financial implications.

- Strategic Supply Chain Management: Develop strong relationships with reliable American suppliers and implement robust inventory management techniques.

- Targeted Marketing: Highlight the unique value proposition of "Made in America" products – quality, sustainability, and support for American jobs – to resonate with consumers.

- Government Resources: Explore government programs and incentives designed to support reshoring initiatives. The [link to relevant government website] offers valuable resources and assistance.

The Future of "Made in America"

Despite the initial setbacks, Miller remains committed to her "Made in America" approach. She's adapting her business model, refining her marketing strategies, and exploring new avenues for cost optimization. Her story serves as a powerful reminder that while the benefits of reshoring are significant, careful planning and a realistic understanding of the challenges are crucial for success. The "Made in America" movement is evolving, and businesses like Miller's are paving the way for a more sustainable and domestically focused manufacturing landscape. Are you considering a similar journey? Share your thoughts in the comments below.

Thank you for visiting our website, your trusted source for the latest updates and in-depth coverage on "Made In America" Test Yields Unexpected Results For Business Owner. We're committed to keeping you informed with timely and accurate information to meet your curiosity and needs.

If you have any questions, suggestions, or feedback, we'd love to hear from you. Your insights are valuable to us and help us improve to serve you better. Feel free to reach out through our contact page.

Don't forget to bookmark our website and check back regularly for the latest headlines and trending topics. See you next time, and thank you for being part of our growing community!

Featured Posts

-

No Savings One In Ten Britons Facing Financial Precarity Says Uk Regulator

May 17, 2025

No Savings One In Ten Britons Facing Financial Precarity Says Uk Regulator

May 17, 2025 -

Analyzing The Effects Of Trump Tariffs On Us Consumer Spending

May 17, 2025

Analyzing The Effects Of Trump Tariffs On Us Consumer Spending

May 17, 2025 -

Double Digit Increase State Farms California Car Insurance Rates Soar

May 17, 2025

Double Digit Increase State Farms California Car Insurance Rates Soar

May 17, 2025 -

Cannes Through A Different Lens Funny And Unconventional Images From Before Digital

May 17, 2025

Cannes Through A Different Lens Funny And Unconventional Images From Before Digital

May 17, 2025 -

Assisted Dying What The Proposed Changes Mean For England And Wales

May 17, 2025

Assisted Dying What The Proposed Changes Mean For England And Wales

May 17, 2025

Latest Posts

-

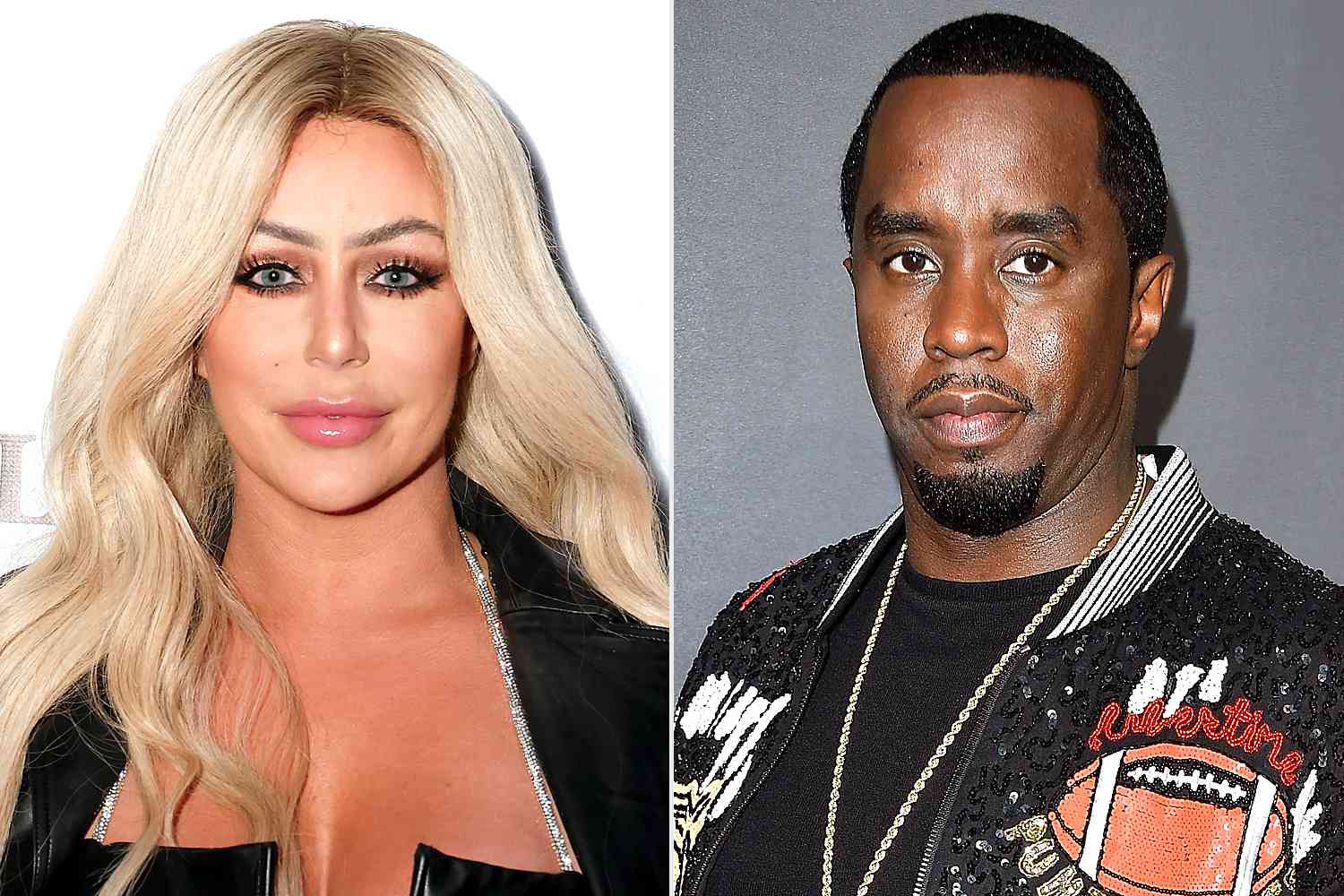

No Testimony From Aubrey O Day In High Profile Sean Diddy Combs Trial

May 18, 2025

No Testimony From Aubrey O Day In High Profile Sean Diddy Combs Trial

May 18, 2025 -

The Week Trump Tried To Make Peace Understanding His Strategies And Goals

May 18, 2025

The Week Trump Tried To Make Peace Understanding His Strategies And Goals

May 18, 2025 -

Vaticano Entra Em Cena Proposta De Mediacao Para O Conflito Russia Ucrania

May 18, 2025

Vaticano Entra Em Cena Proposta De Mediacao Para O Conflito Russia Ucrania

May 18, 2025 -

Unstoppable Twins 13th Straight Win 3rd Straight Shutout Dominate The League

May 18, 2025

Unstoppable Twins 13th Straight Win 3rd Straight Shutout Dominate The League

May 18, 2025 -

Futebol Americano Em Nova York Times Jogos E Noticias

May 18, 2025

Futebol Americano Em Nova York Times Jogos E Noticias

May 18, 2025